量子點發光二極體(QLED)能以溶液製程為主的技術製作,雖然此技術具有低成本、大面積且與塑膠等可撓性基板相容的優勢,但二十年來 QLED始終受限於穩定及效率的問題。最近,中國科學家發現在結構中添加一層絕緣層,能修正QLED中電荷不平衡的問題,讓外部量子效率提高至20.5%,操作壽命達10萬小時,刷新了QLED的性能記錄。

2013年,QD Vision及麻省理工學院的Vladimir Bulovic及Moungi Bawendi已經將QLED的外部量子效率提高至18%,但這類元件的壽命依然是一個問題。最近,由浙江大學的Xiaogang Peng及Yizheng Jin領導的研究團隊藉由有效且平衡地注入電荷,一舉解決了困擾多年的效率及穩定性問題。

Lin指出,QLED的基本問題在於電子及電洞的注入並不均衡─電子過剩而電洞不足,為了減緩電子的注入,這個由浙大、中科院苏州纳米技术与纳米仿生研究所及南京工業大學合組的團隊,在結構中添加了一層絕緣層。為了測試絕緣層的效果,他們採用特別設計的量子點,該量子點具有高量子產出、適合溶液製程及合適的能帶結構。

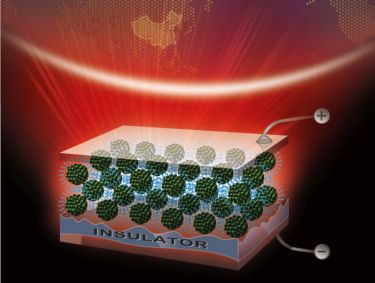

最後的LED結構是由夾在氧化銦錫(ITO)及銀電極之間的六層材料所構成:在CdSe-CdS核殼量子點之下是用來協助輸送電洞的導電聚合物層,負責電子傳輸的是氧化鋅奈米微粒層,該層與量子點間則以絕緣的聚甲基丙烯酸甲酯(PMMA)層隔開。

此QLED完全能以溶液製程製作,只有銀電極例外,不過該團隊說,最近有研究顯示噴墨印刷或其他與塑膠相容的方法也能處理銀電極層。Jin表示,採用工業級設備還能再提升此QLED的壽命。目前他們研究的樣品是發紅光,接下來將會推廣至其他色光。詳見Nature 515, 96–99 (2014) | doi:10.1038/nature13829。

Quantum dot LEDs (QLEDs) are readily fabricated by solution processing techniques that are low-cost and compatible with plastics, and flexible substrates, as well as large areas. Despite these advantages after almost two decades of research stable and efficient QLED designs remain elusive. Now researchers in China have demonstrated that adding an insulator layer in the design structure can correct some of the charge imbalance in QLEDs. As a result they can achieve an external quantum efficiency of 20.5% and operational lifetime of 100,000 hours – a record level of performance.

Best reported performance for solution-processed red QLEDs

Best reported performance for solution-processed red QLEDs

The interdisciplinary team led by Xiaogang Peng and Yizheng Jin at Zhejiang University, China, successfully tackled an issue that had been plaguing QLED researchers for years. "Our study addressed efficient and balanced charge injection which increases both efficiency and stability," says Jin.

Progress in the QLED designs made a leap in 2013 when QD Vision and MIT professors Vladimir Bulovic and Moungi Bawendi made QLEDs with 18% external quantum efficiency – a significant improvement on previous designs. However the lifetime for these QLED devices remained a challenge.

"To be honest we didn’t expect the device lifetime [of our QLEDs] to be so good," adds Jin. "But after we got the data it made sense because the device is so efficient – nearly all charge injected into the device is used, which makes it so stable."

All in the balance

The fundamental problem with quantum dot LEDS is the imbalance between electron injection and hole injection, says Jin. "We can see this because when we make an electron-only device the current density is significantly higher than for a hole-only device."

While the root cause of QLED performance issues has been well known in the field, until now no-one had demonstrated a solution. "We knew the electron injection is in excess and that the hole is not enough so we thought of adding an insulating layer to slow the electrons down," said Jin.

Fabrication challenges

The new design was created by researchers at Zhejiang University, Suzhou Institute of Nano-Tech and Nano-Bionics, and Nanjing Tech University. To test whether adding an insulating layer could improve performance the team needed to use specially designed quantum dots and here the expertise of Xiaogang Peng, as a synthetic chemist particularly interested in quantum dots, was valuable. The quantum dots must have high quantum yield, good solution processibility and proper band structure.

Jin’s materials chemistry research at the Zhejiang University Center for Chemistry of High-Performance and Novel Materials focuses on solution processing for optoelectronic devices, and he emphasizes the care needed to choose the right solvents. "The wrong solvent might dissolve other layers and cause mixing," he tells nanotechweb.org.

The final structure consisted of six layers sandwiched between an ITO electrode and a silver electrode. Conducting-polymer layers beneath a layer of CdSe–CdS core–shell quantum dots helped towards hole transport and a ZnO nanoparticle layer provided the electron transport. A layer of insulating poly(methylmethacrylate) (PMMA) provided the key insulating layer between the quantum dots and the ZnO nanoparticle layer.

The LEDs were fully solution processed except for the silver electrode, which was added by vacuum deposition. That said, recent reports have confirmed that ink-jet printing or other methods compatible with plastics could also apply the silver layer.

On hearing of these latest results, Vladimir Bulovic who led the MIT team in their 2013 research with QD Vision commented, "The continuing climb in the performance of high-efficiency QLEDs could lead to their use in energy-efficient flat-panel display technologies. The solution processability of QLEDs could enable their compatibility with the latest fabrication techniques developed for scalable OLED manufacturing."

Next steps

According to Jin the QLED lifetime could also be improved further by using industry-level equipment instead of the university kit. In addition, the LEDs in the current study were red and next the group will look into applying the approach to LEDs of other colours.

"LEDs are very important – this year’s Nobel Prize was awarded for LED research," points out Jin. "We believe that QLEDs by solution processing may play an important role in the future of this technology."

原始網站:http://nanotechweb.org/cws/article/tech/59094

留言列表

留言列表