(Courtesy of EPC)

Yole Développement interviewed Dr. Alex Lidow, CEO and Co-founder of Efficient Power Conversion (EPC). Recently EPC released eGaN FETs for Class A RF Amplifiers.

Send to a friend

According to Yole Développement technology and applications analysis (detailed in the new Power GaN report), Power GaN exhibits a projected 2020 market size for devices of almost $600m, leading to approximately 580,000 x 6” wafers to be processed. That revenues will be made of 200V first then 600V devices, addressing DC-DC converter, power supplies then ultimately automotive sectors.

Yole Développement: Can you present EPC and its different activities, know-how, devices and markets?

Alex Lidow: EPC is the world’s largest producer of gallium nitride transistors for power conversion. Our products have been widely available since March 2010 and span a range from 30 V to 200 V. EPC’s products are all enhancement mode transistors in chipscale packaging.

YD: Overall, how does EPC envision the future of GaN power electronics?

AL: GaN technology is capable of much higher performance than silicon in power conversion applications. GaN-on-silicon is also proving to be lower cost than equivalent voltage and on-resistance silicon MOSFETs. As a result of the superior performance and lower manufacturing cost, GaN-on-silicon will broadly replace silicon in new power conversion applications and will consume a large fraction of the existing applications for power MOSFETs, LDMOS, and IGBTs up to 600 V.

YD: In one of your latest press-release, you entitled “Power Conversion: The End of the Road for Silicon”. Can you explain how you envision GaN market penetration over incumbent Si technologies? What application and when? Which applications fit best with GaN today? And tomorrow?

AL: The rate of GaN-on silicon’s penetration of the power conversion market is dependent upon the answers to four key questions:

- Does it enable new applications

- Is it easy to use

- Is it very cost effective

- Is it reliable enough for the application

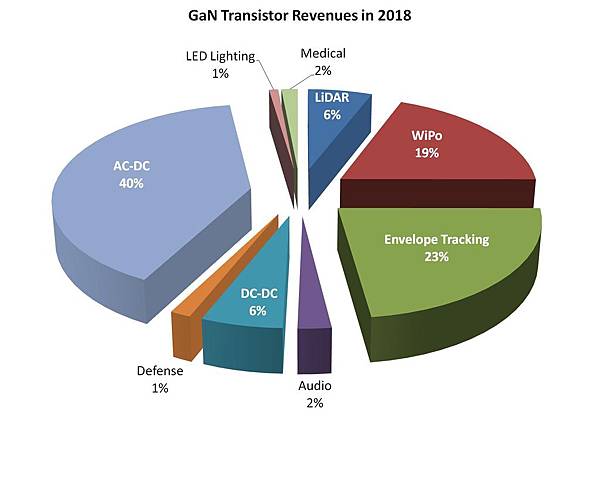

The driving force behind GaN adoption today are applications that fit into #1 above – new enabled applications. In 2018 we expect half of the GaN revenues to come from these enabled applications. Examples are Envelope tracking, wireless power and LiDAR. Below is a pie chart showing the expected revenue breakout for GaN transistors in 2018. About half of the revenue will come from these three applications.

YD: EPC now proposes a full set of GaN FET from 40V to 200V. How about 600V? Will it soon be release on the market place?

AL: The end market for transistors below 200 V is much larger than the market for 600 V according to IC Insights. The lower voltage market is also much more performance-sensitive. EPC has therefore initially focused on this larger and faster-growing market. We expect to expand into 600 V products near the end of 2014.

YD: In recent moves, GaN/Si devices demonstrators with high voltage (600V) and high current (> 100A) have been shown and could reach market before 2020. What about EPC device roadmap on power applications? Is EPC focusing on 200V devices or are you willing to catch up GaN/Si value for 600V/High current applications?

AL: EPC will enter the 600 V markets with an enhancement mode device near the end of 2014.

YD: How do you see automotive applications taking benefit from GaN? What is still missing for GaN technology to address this market?

AL: The automotive market will use GaN in many applications over the next few years. Today GaN transistors are in automotive lighting. Soon they will also be in sensors of all kinds using LiDAR technology (GaN-powered LiDAR is used in all autonomous vehicles). In the longer term GaN will also be used in EV traction drives for electric and hybrid vehicles, as well as a host of safety applications such as ABS and traction control. The auto industry is relatively conservative in their adoption of new technologies in safety and drive train applications. We anticipate broadscale adoption of GaN in these critical drivetrain and safety functions somewhere around 2020.

YD: What are the main technical and non-technical drivers using GaN in power conversion apps?

AL: From the experience with power MOSFETs in the early 1980’s we learned that there are four key drivers for the adoption of a new technology:

- Does it enable new applications

- Is it easy to use

- Is it very cost effective

- Is it reliable enough for the application

There is ample evidence that the answer is yes to all four questions with respect to GaN-on-silicon

YD: Is the extra-cost of GaN balanced by real and proven added-values at system level?

AL: Certain GaN-on-silicon products from EPC already cost less to produce than a comparable power MOSFET or LDMOS transistor. Within 2 years GaN-on-silicon will broadly be lower cost to produce than their silicon counterparts.

There are many applications where the added performance of GaN justifies a price significantly higher than a comparable MOSFET, IGBT, or LDMOS transistors. Four examples are:

- Envelope tracking

- Wireless power transmission

- LiDAR

- Radiation tolerant transistors

YD: Azzurro recently went bankrupt. Is it a sign that GaN epi will continue being done in-house, at device maker level?

AL: Commercial sellers of GaN epi will need to realize that the cost structure will need to be within a factor of two of silicon epi wafers. Unless they can make an adequate profit at that cost there will not be a large market for their product.

YD: SiC is now well established in some selected applications (PV inverter, PFC, train traction). Can GaN catch-up and capture market shares over SiC? What is the upper voltage/power limit where definitely GaN won’t compete with SiC?

AL: GaN and SiC have distinctly different strengths. GaN-on-silicon is lower cost and higher performance compared with SiC at or below 600 V. Applications above 900 V are best served by vertical transistors. GaN-on-silicon is not the best format for a vertical device. Until GaN-on-GaN becomes cost effective, SiC will dominate.

YD: Is Normally off a “must-have” or is there applications where Non can still play a role?

AL: Normally off (enhancement mode) is a “must have” for power conversion. RF transmission can tolerate normally on (depletion mode) power devices.

YD: Since GaN/Si components have to be integrated both with a power module and a gate driver circuit, don’t you thing that development of low inductance, low Rth power module with GaN gate driver (in case there is no cascode) is now on the critical pathway for GaN/Si devices volume application? What is EPC policy on these two topics?

AL: EPC, eGaN FETs are sold “packageless”. We believe that below 200 V there is no need for a traditional package. A package only adds cost, consumes space, degrades reliability, adds thermal and electrical resistance, and adds inductance.

Drivers eventually will be integrated into the GaN power stage (GaN Systems is already demonstrating such a product).

EPC technology (an eGaN® FET) in front of end applications adopting this technology

(Courtesy of EPC)

Source:YOLE

留言列表

留言列表